In industry, caster wheels are extensively used to assist in smooth movement of heavy furniture and other items.

Your choice of caster wheel to roll away a movable heavyweight item should be based on multiple factors such as texture of the floor, weight of the item and load-bearing capacity of the wheel.

On an even floor, a large diameter wheel and a small diameter wheel function equally well. However, it can happen only in a perfect environment that is not found in the real world. If you need to use the wheels outside, debris and bumps are common finds on the ground. In such cases, larger wheels make the ideal choice to roll the loads over the bumps and debris as smoothly as possible.

You can use a wheel with a diameter ranging between 2-inch to 12-inch, depending on the loads to carry. If you base your choice on only the load-carrying capacity of the wheel, you are more likely to get a small wheel capable of pushing safely.

Wheels with larger diameters enable the users to pull and push the cart easily. However, diameter should not be the only factor to figure out in your consideration, especially in times of retrofitting a used cart. There are multiple advantages of using larger wheels as these can easily switch between their loading characteristics. They can move the centre of gravity and the feature enables easy and quick loading.

If you intend to push extremely heavyweight items – for example, over 2,000 pounds –it is better to go with wheels having 10-12-inch diameter. However, the industrial caster wheel manufacturers claim that wheels with 8-inch diameter are more popular.

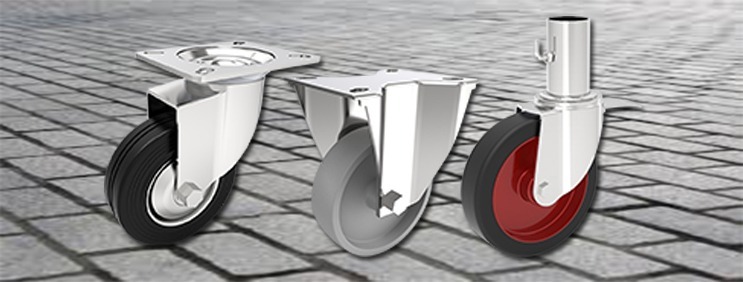

Design of Caster Wheels

Theses wheels have inner base, outer tread as well as rotating bearing. The straight wheel bearing comprises alternating small and large rollers. Those rollers need periodical lubrication. Wheels can have tapered bearing as well. This type is perfect for rolling heavy loads. Precision ball bearings have become most popular in recent years as they are sealed and need no lubrication periodically.

Many caster wheel manufacturers now offer double-sealed precision ball bearings. These are completely sealed. The best part is these require the workers to exert little pressure for rolling. You don’t need to grease these bearings. Manufacturing of such bearings brought a revolutionary change in the industry and heavily affected machine ergonomics and maintenance.

If you are confused about making a choice from a wider variety of caster wheels, consult an expert in this field to spend on the right piece.