The castor wheel manufacturing industry is a large one, and for any potential buyer, it is important that they choose the top castor wheel manufacturers in India for reliability and efficiency. Here is a guide to choosing the right kind of castor wheels;

Considerations while choosing a castor wheel

• Diameter of the wheel: As it is easier to roll larger wheels, you would require the largest possible wheel, but do not select such a large wheel that it would raise the center of gravity so significantly that the load may topple.

• Swivel Radius: This is not important if you go for a fixed castor, but if the castor has to swivel, you have to know the amount of clearance required to achieve a 360 degree swivel when the castor is mounted.

• Load Capacity & Dynamic Load: Castors are designed to support a certain maximum load, and exceeding this load would stress the castor wheel to the point of failure. This could result in very damaging results, both economically and physically; you have to divide the maximum potential load by the maximum load capacity of the castor to arrive at the required number of castors.

• Rolling ability: You also need to choose the right bearing so that the castor rolls well when in use. Having an efficient precision ball bearing makes this job easy.

• The Brakes: Many different braking options are available, and each has its own advantages. Friction brakes and side brakes are quite economical and tread and top locks provide more positive locking wheels.

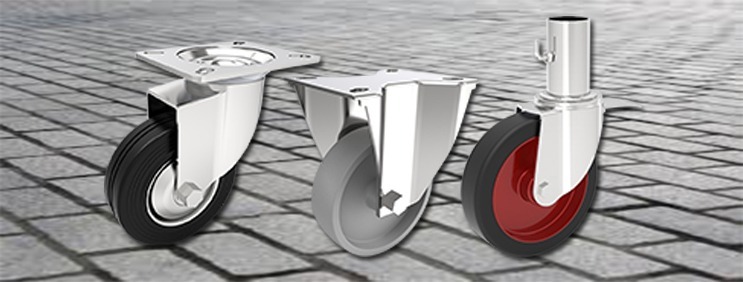

• The Mounting: There are different ways to mount the castor wheel, and they include top plates, screw threads and press threads.

Castor materials

• Polypropylene: This is an economical option for wheel material but due to its hardness, it does not offer noiseless movement. This type of material is well suited for hard factory floorings.

• Black Rubber: they have lower load capacities than hard rubber castors, but they compensate by additional floor protection, quiet movement, and a highly cushioned ride for fragile loads.

• Polyutherane: This has a hard tread and it gives very good floor protection and also provides resistance to cuts and scratches on the wheel.

• Cast Iron: This is a hard wheel material and it is quite durable and strong. It does not wear away at all and the only concern is exposure to water, which will form rust.

With so many options open to you, it is only a matter of judicious planning and calculation, so that you arrive at the perfect castor wheel for your intended application. Check out www.comfortcastors.com for more details.