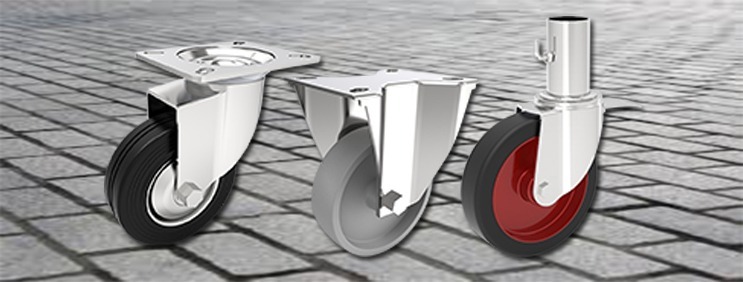

Castor Wheels generally come in three forms, fix type, swivel type and brake type. In this blog we will identify the differenced between these three types for a better understanding of casters and their use in the industry

Swivel Castor Wheels

These casters are the most commonly used term in online searches and offline stores. Castors are generally used because of their swivel action and thus can help the trolleys move in any direction with little effort. These castors can rotate 360° to enable smooth movement of the loading equipment. The swivel castors are generally installed at the front of the trolley to enable direction. The swivel section of the castors can be made either through double ball raceway, kingpin less mechanism or integration of ball bearing or thrust bearing. These different types of mechanism along with the load can affect the final movement of castors. Thus before choosing a swivel castor, one should definitely ask the castor wheel manufacturer of the type of swivel section. The most common is double ball raceway swivel section but it also the most economical. Kingpinless swivel castor with thrust bearing is the best for a durable castor wheel.

Fix Castor Wheels

Fix or Rigid types of castors are the simplest castors to produce and install. They are generally installed at the back of the trolley to provide stability to the trolley or loading equipment. These fix castors are used in combination with swivel castors for a smooth movement of trolley. If the trolley is to be run inside a channel, fix castors are the only option as no swivel action is required. Fix castors are manufactured either through forming of metal sheet or fabrication (welding) of metal legs. One should look at the sheet thickness or the leg design of the castor in choosing the best fix or rigid castor.

Brake Castor Wheels

Castor Wheels with brake are the most complex to manufacture and comes with many types of different brakes as stated under: Swivel Brake: This brake only locks the swivel section, thus a swivel castor can be converted to a fix castor using this option

- Wheel Brake: This brake only locks the wheel and does not stop the swivel action. Thus even if the wheel is locked, the stationary castor can swivel on its own axis which is not recommended.

- Total Brake: This brake locks both the wheel and the swivel section. This is the most common type of brake in demand and also the most suitable for industrial applications. It completely brings the castor wheel to a halt without any skidding.

- Front Brake: This is a total brake, which is operated from the front of the castor. Light duty and medium duty castors mostly use this type of brake

- Back Brake: This brake is installed at the back of the castor and used mostly in applications like scaffolding and wastebin industry.

The above article comprehensively defines the major differences between the various types of castors available in the market. If you would like to know more about them or would like to examine some castor wheel samples, please write to us at sales@comfortcastors.com or browse our product page to chose the right castor wheel for your need.